| IMPERIUM DYNAMICS

A phased approach to Digital Transformation

Digital transformation refers to the integration of digital technologies into all areas of a business, fundamentally changing how companies operate and deliver value. For manufacturing, it promises immense potential for improving operations and increasing competitiveness. Technologies such as IoT, AI, and automation are at the forefront of this transformation, enabling manufacturers to streamline production processes, optimize supply chains, and enhance overall efficiency. However, despite its potential, only 30% of manufacturers are able to adopt this transformation, as indicated by a McKinsey survey.

There are good reasons for this, too. Delivering such fundamental change at scale in large, complex organizations is challenging, especially with short-term pressures. Manufacturing leaders are reluctant to invest in new technologies or processes because the short-term financial justification is challenging. Putting their careers on the line for an investment that doesn't show immediate returns feels too risky in a bottom-line-driven environment.

This short-term view overlooks the long-term, intangible benefits of digital transformation, such as improved employee engagement, brand differentiation, and new business models.

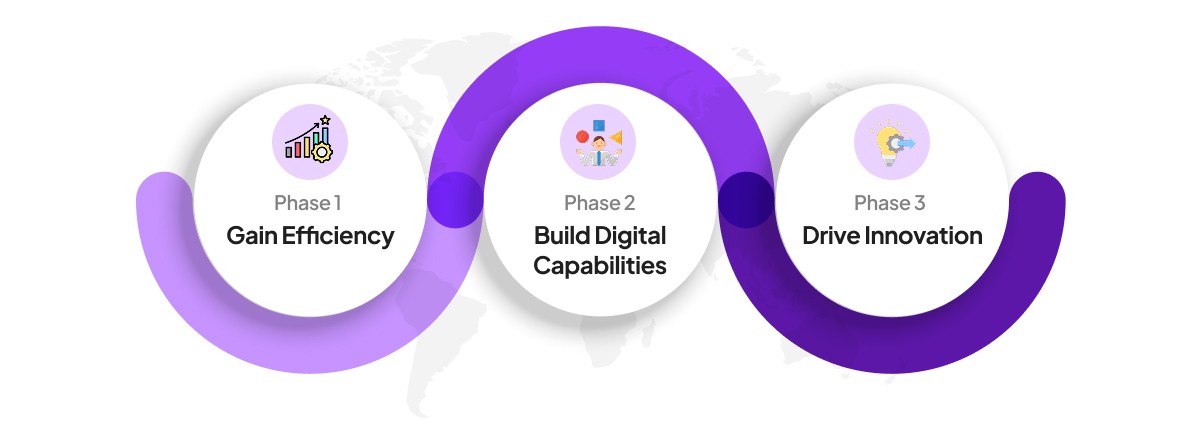

To address this challenge, experts, including those from MIT Sloan Management Review, suggest that manufacturers adopt a phased approach to digital transformation. Rather than viewing it as a large, one-time project, this approach breaks down the transformation into manageable steps, allowing businesses to progressively adopt digital technologies in a way that aligns with their capabilities and long-term goals.

Phased Approach to Digital Transformation

Digital transformation is not a singular, one-off initiative; it’s a continuous journey that requires thoughtful planning, careful execution, and the right metrics to evaluate long-term success—not just immediate financial returns.

For transformation to have a lasting impact, manufacturers should approach it in phases, each with clear objectives, tools, and measurable outcomes. To bring this approach to life, we can look at real-world examples, such as those from Microsoft Customer Stories, to see how this can be effectively applied.

Phase 1: Gaining Efficiency

The first phase of digital transformation is focused on driving operational efficiency, lowering costs, and enhancing productivity in specific parts of the value chain. In this stage, manufacturers should prioritize clear, measurable outcomes like ROI, cost reduction, and productivity gains.

In 2018, Metinvest, a vertically integrated steel and mining group, embarked on a project to improve blast furnace fuel efficiency. The company utilized digital technologies to predict the silicon content in iron, a crucial factor affecting furnace heat. Even small adjustments in silicon levels could lead to significant reductions in fuel consumption.

By implementing an AI-driven machine learning program, Metinvest used real-time data to predict silicon content. The insights were then made actionable through Azure Machine Learning, and operators could adjust the furnace settings using a Power BI dashboard. The results were tangible—Metinvest achieved a return on investment valued at $100 million, highlighting the importance of measurable outcomes in this phase.

Phase 2: Building New Digital Capabilities

The next phase of digital transformation involves enhancing a company’s digital infrastructure to improve data flow and streamline supply chain integration. Here, success is measured by factors like system implementation time, user adoption, and customer satisfaction.

Bel Fuse, a manufacturer of electronic components, faced significant challenges with its legacy ERP system, which was cumbersome to update and costly to maintain. The company needed a more modern solution to support its material requirements planning (MRP) and enhance its operational efficiency.

By migrating to Microsoft Dynamics 365 Finance and Supply Chain Management, Bel Fuse was able to integrate its data and improve supply chain agility. While cost savings were a benefit, the primary success lay in reducing dependence on external vendors by leveraging internal expertise. This shift not only optimized operations but empowered internal teams, marking a significant step forward in the company’s digital transformation.

Phase 3: Driving Growth Through Digital Innovation

Once a company has built a solid digital foundation, the next phase is to leverage its digital capabilities to create innovative business models and ecosystems. At this stage, the focus shifts to customer engagement, brand trust, and digital partnerships.

Aditya Birla Fashion & Retail Limited’s Example

Aditya Birla Fashion & Retail Limited (ABFRL), a leader in fashion retail, faced challenges with inventory management and slow data refresh cycles that were causing checkout delays. Their legacy systems couldn’t keep up with the demands of a seamless customer experience, which affected both security and service standards.

Through digital innovation, ABFRL integrated mobile POS systems with Dynamics 365 Commerce, enabling them to operate flexible pop-up stores and adapt quickly to emerging market opportunities. This digital capability allowed ABFRL to scale rapidly, expand its market presence, and provide a more integrated omnichannel experience across mobile, online, and in-store platforms.

The company’s ability to leverage data-driven insights to refine marketing strategies, and optimize inventory, and personalized services led to improved customer satisfaction and higher sales. This example illustrates how digital infrastructure can be used to innovate and drive growth in ways that were previously unimaginable.

Conclusion

Digital transformation presents significant opportunities for manufacturers to enhance efficiency, foster innovation, and drive long-term growth. While challenges such as short-term financial pressures may hinder adoption, a phased approach allows manufacturers to manage change incrementally, ensuring alignment with strategic goals. By leveraging technologies like IoT, AI, and automation, manufacturers can improve operational performance and create new business models, ultimately gaining a competitive edge in the evolving market.